Magnetic Actuated Vascular Guidewire Robot with Cosserat-Rod Modeling (To be Submitted)

Overview

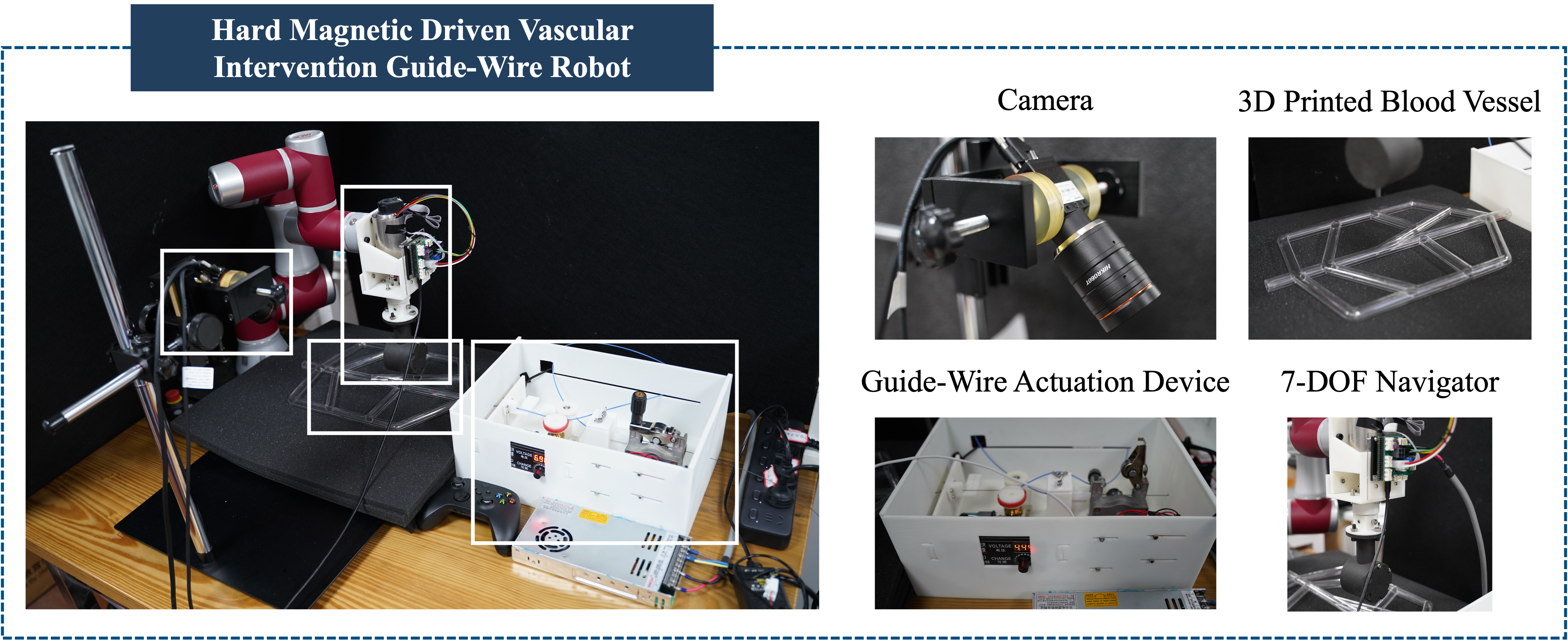

This project develops a magnetically controlled vascular interventional guidewire robot and its control software, aimed at reducing surgeons’ X-ray exposure and improving accuracy in minimally invasive cardiovascular procedures. A hard-magnetic guidewire is actuated by an external permanent magnet mounted on an industrial robot, enabling precise bending and navigation inside tortuous blood vessels.

System Architecture

The full system integrates two subsystems:

- Manual teleoperation platform

- Uses an Xbox wireless controller as a unified input device.

- One controller simultaneously drives the industrial robot, the guidewire feeding mechanism, and the distal rotary motor.

- Real-time signal processing strategies ensure low latency and allow human intervention in abnormal situations.

- Software control platform (PC, Qt/PyQt)

- QtDesigner-based GUI with a script editor, console output, camera view, and one-click “macro” buttons.

- Supports Python scripting of high-level procedures, real-time feedback, and an emergency stop that safely halts all devices via multi-threaded control.

- Combines the flexibility of manual control with the precision and repeatability of automatic control.

Large Deformation Modeling of the Guidewire

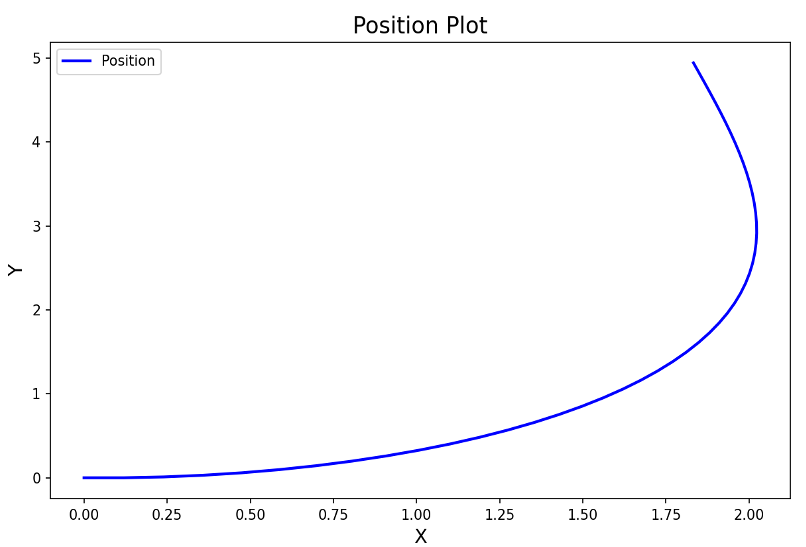

To accurately predict the guidewire shape under magnetic actuation, the project builds a Cosserat-rod-based large deformation model:

- Models the guidewire as a slender rod undergoing bending, torsion, stretching, and shear, overcoming the limitations of constant-curvature and classical Kirchhoff models.

- Discretizes the rod with a finite-difference scheme; derives the coupling between position, orientation, curvature, and internal forces/moments.

- Incorporates the magnetic torque from both uniform fields and a magnetic dipole field generated by the external permanent magnet, enabling simulation under realistic spatially varying fields.

These simulations are later tabulated to build a mapping from magnet pose to guidewire tip deflection, serving as the basis for automated path-following control.

Experimental Validation

A transparent, 3D-printed vascular phantom with multiple bifurcations is used to emulate patient-specific vasculature. The complete system—manual controller, software platform, vision feedback, and magnetic actuation—is evaluated on two key tasks:

Automatic navigation:

The guidewire successfully follows a preset path through complex branches and reaches the target location under autonomous control.Error detection and correction:

When the guidewire unintentionally enters a wrong branch, the system:- detects the deviation via vision,

- retracts the guidewire to the previous node,

- updates the expected magnet pose using the theoretical model,

- and re-advances along the correct path.

My Contributions

- Designed and implemented the unified manual control framework (Xbox controller → PC → robot, feeder, and distal motor), including real-time filtering and signal routing.

- Developed the Qt/PyQt software platform, GUI, scripting interface, one-click macros, and multi-threaded emergency stop logic.

- Formulated and implemented the Cosserat-rod-based large deformation model for the hard magnetic guidewire, including finite-difference discretization and magnetic loading.

- Conducted experiments in 3D-printed vascular models, integrating vision feedback and control algorithms to demonstrate fully automatic navigation and error correction.